This is the sixth post in a series documenting my method of construction for an entire set of custom kitchen cabinets. This series is not intended to be a full how-to tutorial, but rather to show the sequence of steps using photos and commentary. You can find all the posts in the series here. Please comment below or send follow-up questions to jonathan@jmoncton.com.

This next step is one of the elements that separates this method of cabinetmaking from many others. I will create a large shoulder on the edge of each cabinet side for the top and bottom panels to fit into. This shoulder will be allow the panels to be glued and screwed together forming a very strong joint.

I will cut this shoulder in two steps on the table saw. After setting the rightmost edge of the blade exactly 20mm from the fence, and setting it 15mm high, I run the panel through the saw, using a push block to press the panel down to the table.

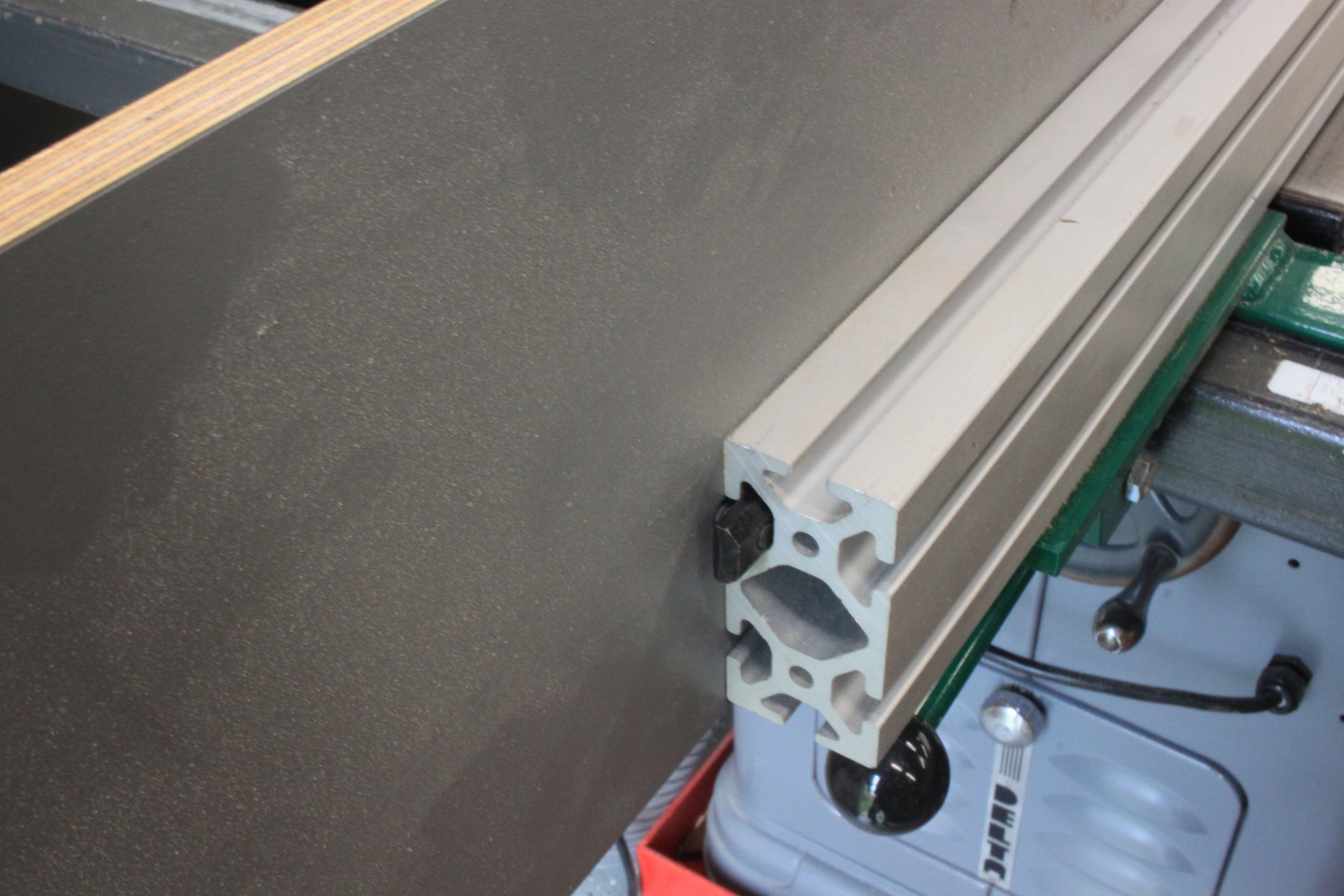

Once both ends of each panel have been cut this way, I install the tall auxiliary fence into the tracks on my aluminum fence since the panels will be run through the saw vertically. I check to make sure the fence is square to the table and set it at 3mm to the right of the blade.

To help press the panel against the fence I have a piece of wood with a shoulder cut out of it. This avoids putting pressure on the waste piece that would make it kick back while keeping the panel perfectly upright.

Here is the resulting shoulder after making these two simple cuts.

Now the sides are ready to receive their solid wood edge banding. Here is what it looks like with the banding applied.

While that is being done I cut a notch in the trim on the tops and bottoms to fit with the shoulder I have just cut on the sides. In the picture below the trim on the top piece intersects with the trim from the lower piece. That is the portion to be removed.

This cut is performed in two quick steps on the table saw. Using a stop block attached to my fence, and pushing the piece through with the miter gauge I can make accurate, repeatable cuts in the trim.

Thanks for reading. Up next I will demonstrate my method of trimming the edge banding flush with the panels and begin sanding.