This is the tenth post in a series documenting my method of construction for an entire set of custom kitchen cabinets. This series is not intended to be a full how-to tutorial, but rather to show the sequence of steps using photos and commentary. You can find all the posts in the series here. Please comment below or send follow-up questions to jonathan@jmoncton.com.

Prior to applying the final finish coat I lay out and drill holes for all the hardware that is mounted to the cabinet sides. I will start with the Blum hinge plates – the piece that is mounted to the cabinet that accepts the door hinge.

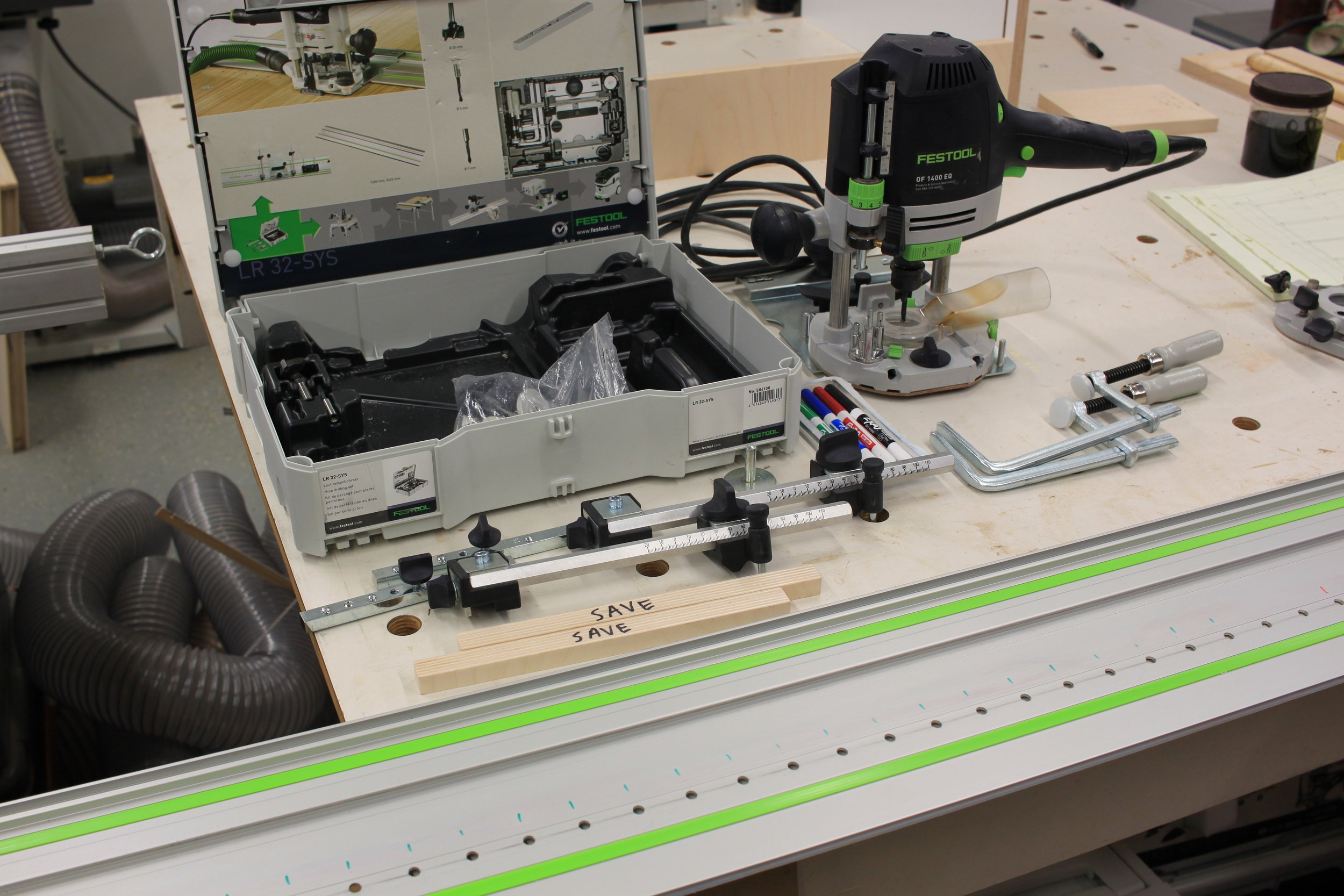

The Festool LR32 system paired with my OF 1400 plunge router makes this part very simple.

All of the components of this system except the router and guide rail fit in this small box. Before I go further I want to recognize a great source of detailed information on how to use the LR32. Eric at The Poplar Shop is as entertaining as he is informative, at least for a woodworking channel on YouTube.

I start by clamping my panel to the end of my table saw with the panel end overhanging the edge.

The LR32 system uses multiples of 32mm as the basis for layout. It works best if the height of the cabinets is in a multiple of 32mm, like this lower base cabinet that will be 768mm tall (32 x 24). Since I make my cabinets with a shoulder, I add these simple spacers that sit in the shoulder on each end to get to the final height.

Next the end stops are installed into the guide rail with the 16 up & out. They are located along the rail so the rail fits over the panel exactly. If the panel is accurate there will be no play in the rail.

The rail is then place on the panel and the side stops are attached to the rail, set at exactly 37mm. This dimension will be the distance from the edge of the panel to the center of the hole that is drilled.

With the side stop pins pressed to the edge of the panel, the clamps are inserted along the track and clamped to the panel.

Once the track is securely clamped, the side stops can be removed. They are only used for locating the rail relative to the edge. Next I prepare the router by first installing the LR32 base plate and calibrating it. Calibration is very simple and instructions are included for this in the box. Then I install the included 5mm brad point bit and set the router depth to the height of these 6.3 x 13mm mounting screws since that is what will be used to attached the hinge plates.

Now I am ready to place the router on the rail and plunge in the appropriate locations, marked in red dry erase marker on the rail. The base plate that has been installed on the router indexes on the guide rail holes.

The brad point bit cuts a very clean hole exactly in line with the holes on the rail, and the dust is all collected.

Checking the hinge plate for fit.

Later this same system will be used to bore the 35mm hole for the hinge, locating exactly halfway between the two hinge plate holes on the cabinet door.

Thanks for reading. Next I will lay out and drill all holes for the drawer slides.